Frequently Asked Questions

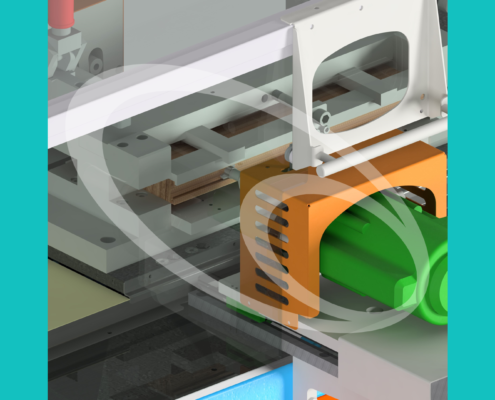

- Are the machine’s cutting heads interchangeable?

The cutting heads (tools) are interchangeable.

- Approximately how long does it take to set up?

Time of electrical connection to your network. The machine is ready for use.

- When the pieces to be cut are inserted into the fixture?

Average loading time 30”-40” (seconds).

- We would also like to know the average cycle time of the machine,

Average working time 80”-100” (seconds).

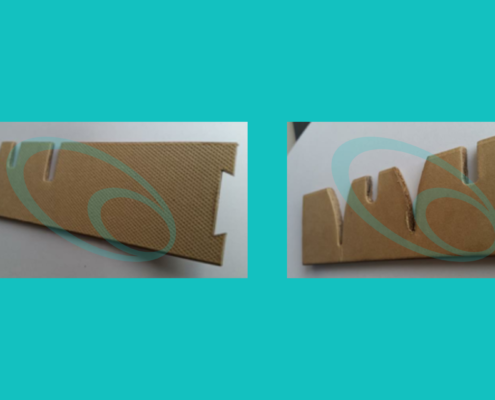

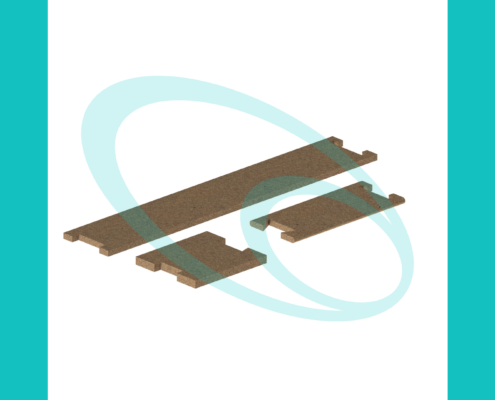

- What is the number of parts in this cycle?

The capacity of the load is 500 mm. The number of spacers depends on their thickness.

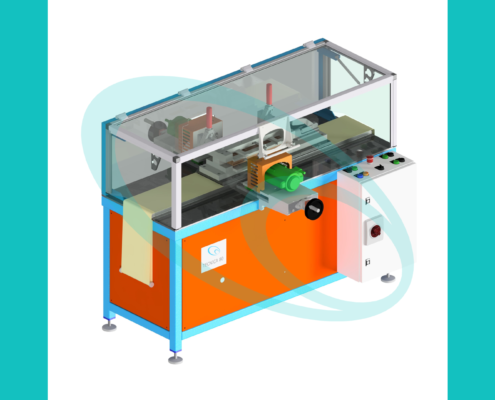

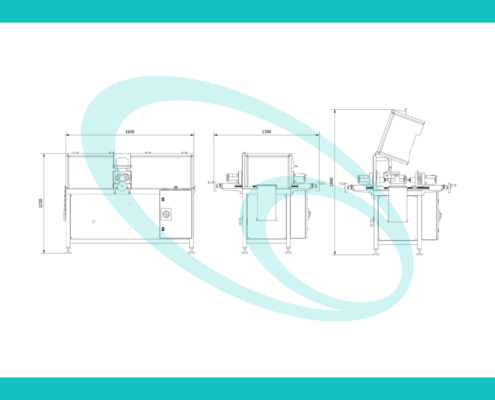

- The dimensions of the MMS:

Length: 150 sm | Width: 90 sm | Height: 160 sm | Weight: 150 kg

- Does MMS require any special installation?

This equipment doesn’t require any special installation. It is preferable to have a hose connected to the air pump, for cleaning the equipment from dust after usage.

- What is the electrical information of MMS?

Electrical information is the following: 220-380V, 7kW, amperage is standard.