Description

The original name in Italian is Dispositivo rullo di pressione.

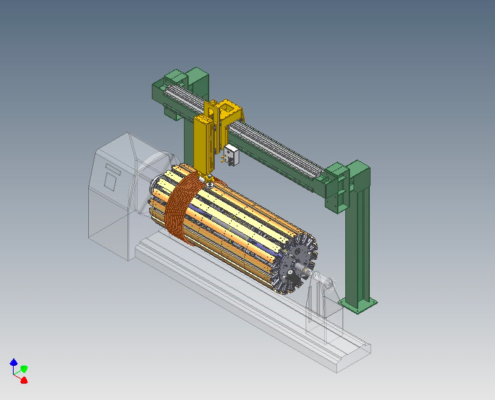

A Press Roller Device in the transformer industry is a specialized mechanical tool or component used during the winding or assembly process of transformer coils. Its primary purpose is to exert controlled pressure on the conductor or insulation layers to ensure proper compaction and alignment. This process is crucial for enhancing the transformer’s efficiency, durability, and reliability. Watch the video on YouTube.

Our equipment is engineered with the unique requirements of the transformer industry in mind. It enhances both the quality and efficiency of your transformer assembly, setting new standards for the production process. With our device, you can expect reliable performance that translates into superior product quality.