Precision in Bending

The Hydraulic Benders Model L (90°) were designed to bend the CTC and Straps to 90° without damaging the copper wrapping paper. To gain a clearer understanding, we invite you to watch our engaging video presentation on YouTube.

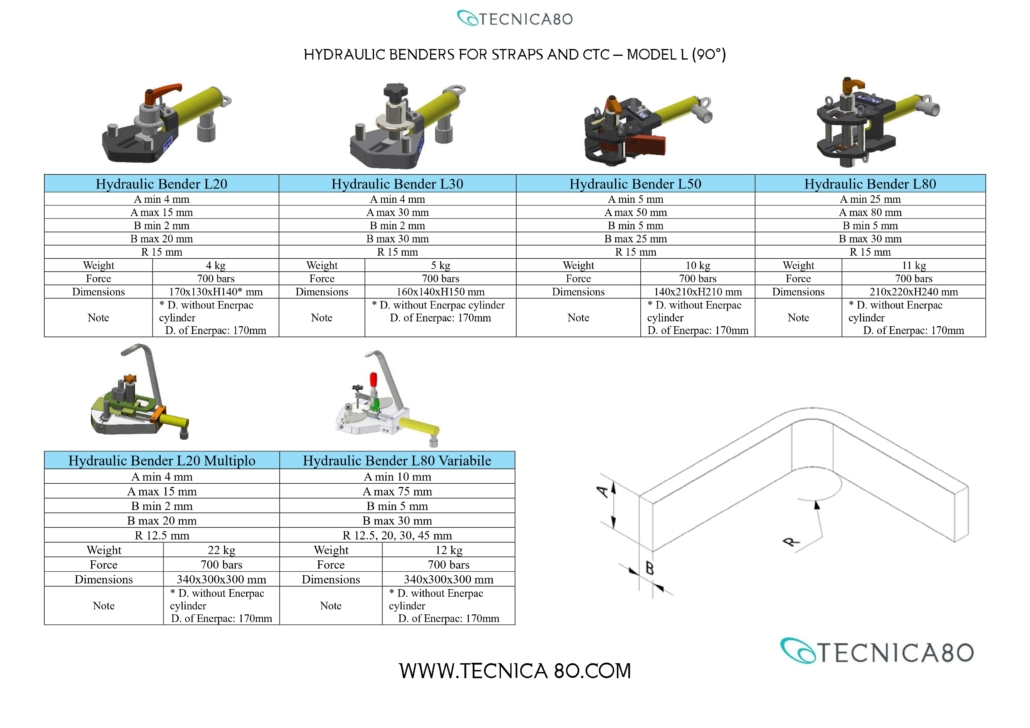

For now there are 6 types Hydraulic Benders Model L (90°):

L20 is the smallest, it bends copper with the following dimensions: A min 4 mm, A max 15 mm, B min 2 mm, B max 20 mm, R 15 mm. R&D is going on the battery powered version.

L20M (Multiplo) is a unique and exclusive model which guarantee the bending of multiple number of copper straps at the same time without damaging them. It bends copper with the following dimensions: A min 4 mm, A max 15 mm, B min 2 mm, B max 20 mm, R 12.5 mm.

L30 is a bestseller model, it bends copper with the following dimensions: A min 4 mm, A max 30 mm, B min 2 mm, B max 30 mm, R 15 mm. R&D is going on the battery powered version.

L50 is a medium-size model, it bends copper with the following dimensions: A min 5 mm, A max 50 mm, B min 5 mm, B max 25 mm, R 15 mm.

L80 is the biggest model, it bends copper with the following dimensions: A min 25 mm, A max 80 mm, B min 5 mm, B max 30 mm, R 15 mm.

L80V (Variabile) is a unique and exclusive model which guarantee the bending of variable types of copper on the same tool, only by changing the adapters. It bends copper with the following dimensions: A min 10 mm, A max 75 mm, B min 5 mm, B max 30 mm, R 12.5, 20, 30, 45 mm.