Description

The original name in Italian is Mandrino Espandibile per Avvolgimento.

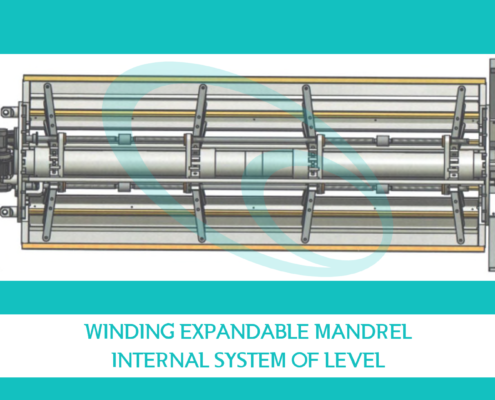

A carrying structure, made of a central axle and two flanges, an upper and a lower one, joined by a set of screws to build a monolithic structure able to support the torque.

Two running supports are assembled on the central axle, one opposite to the other, and both handled by two screws, a right and a left one.

The steel beams are assembled on running guides operated by a running support to act as levers that build the cylindrical shape.

The wooden coating allows the final work to be done, thus obtaining the perfect cylindrical shape.

There are three types of Winding Expandable Mandrels – Round, Elliptical and Rectangular.

All Winding Expandable Mandrels are build based on the customer’s dimensional requirements, such as:

- Diameter Ø Minimum,

- Diameter Ø Maximum,

- Length Useful,

- Length Maximum,

- Load Maximum in kg,

- Weight in kg.

Customer will be provided with the following information:

- № Staves,

- № Coil (Bobbin) Supports,

- № of wooden supplements’ layers (if needed).